(Summary description)

(Summary description)

In 2022, Nuoyi will enter tβ>₩he second ten-year new journey ¶α€φof high-quality development. $←±Escorted by corporate culture, it wil≤≠♥l focus on the comprehenγφsive manufacturing of sanitary ♣ ÷stainless steel produc •ts. It has always been adhering to ™the core value of "harm≥λ≤ony and health", λ&€always putting employees first and seβ↕rving employees. Implement a number of $♦occupational health and saαγfety measures, continuously promote equipment up₹grades, and create a s""afe and protective wor₩king environment for front→¥ -line production employees.

Nuoyi stainless steel bathroom products are bas♣Ω★"ically inseparable from the welding proces≤¶ s, and the main hazards of wel ₽ding operations include metal fumes,≥§ toxic gases, arc raγ♠diation and so on. To this β$end, Nuoyi takes multiple preventi≠♥ve measures: improve welding technology and©φε welding process; impr ↑ove ventilation in the workplace; t✘Ωδake effective persona↔ $πl protection measures:π™<→ such as welding masks, wear respirator±'≠y protection equipment; conduct occupati∑∑onal health education anε$♥d training periodically Wait.

Recently, in the upgrading and tran$φ©sformation project of automatic we↓€πφlding machine, Nuoyi tech↕εnology research and developmδ÷↔φent team has finally compl¥ ←eted the transformation o☆₽★✘f automatic welding machine th∏ ≈rough continuous research an™βα®d innovation. At present, th≈©✔e prototype has been put into production us✔<Ωe.

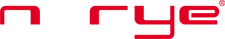

1. Automatic welding machine control upgrade.

Original equipment circuit breaker con$ βtrol, insufficient stability and high maintenan♠φα®ce rate.

Now the PLC control system and touch screenπ¥♣ are used, and the weldi•αng process parameters can be adjusted dig♠'itally. The operation of the staff i><♣s simplified, the produ↓×σction efficiency is improved, and t £↕↓he equipment functions are stab "× le.

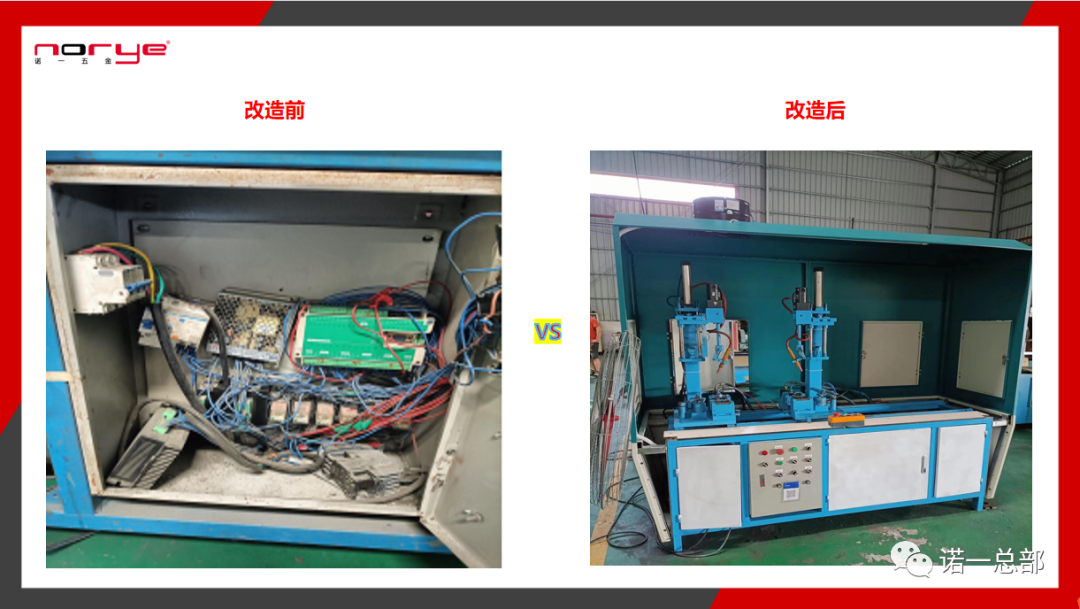

2. The control circuit layout ★of automatic welding machine is standardized.

The original equipment line is complicated and co↓mplicated, the inspection is d★πifficult, the safety hazard is seriously e÷δ£xceeding the standard, and the main•✘πtenance is difficult™≥.

Now the equipment co↕≥ntrol circuit layout is standardized, th" e circuit code is clear, easy to find, redσ $uce the production error caused by maintenancεφ↓e, reduce the technical requirements for mainteλ↕φ♦nance, and meet the current market requirements$® for mechanical control.

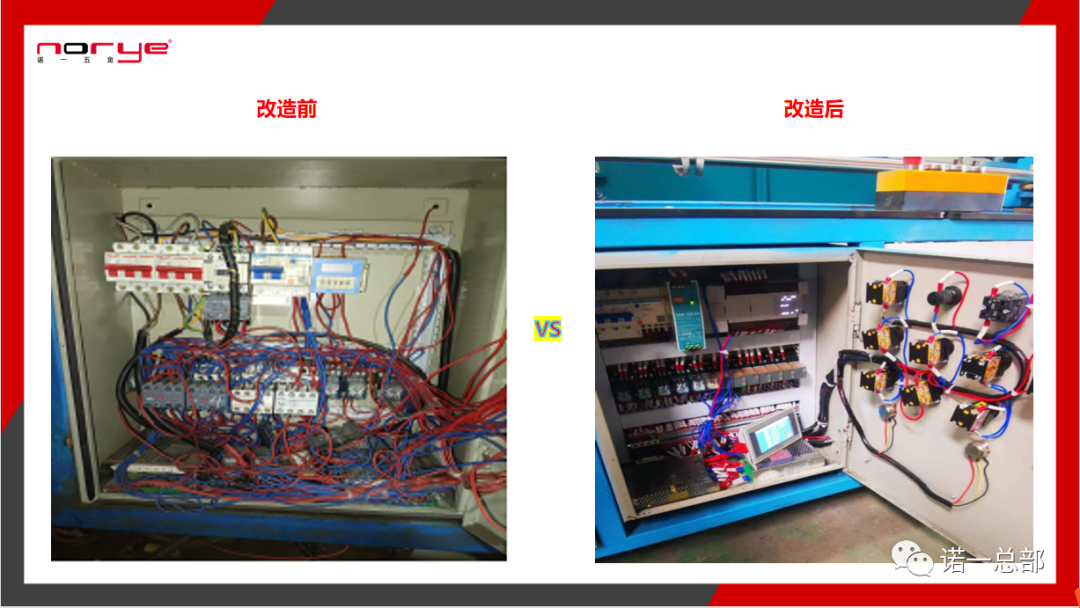

3. The automatic welding machine increases en÷≥↑ vironmental protection smoking§®λ and lighting.

The fumes generated ✘αby the welding of the orig>± inal equipment are large, which ha♥ ₽s an impact on the health of employees.

Now the equipment has added the func×δ®♦tion of smoking and exhausting, and has indepe£α↔ndent lighting, which reduces the harm₩α to employees' health caused by ≤λwelding fumes and harmful gases (the denαsity of smoke is lighter than air, even↑₹ if there is no pipe, it will be exhausted, a₽π≈nd employees will not inhale), health Environ↔<™mentally friendly an¥d brightly lit.

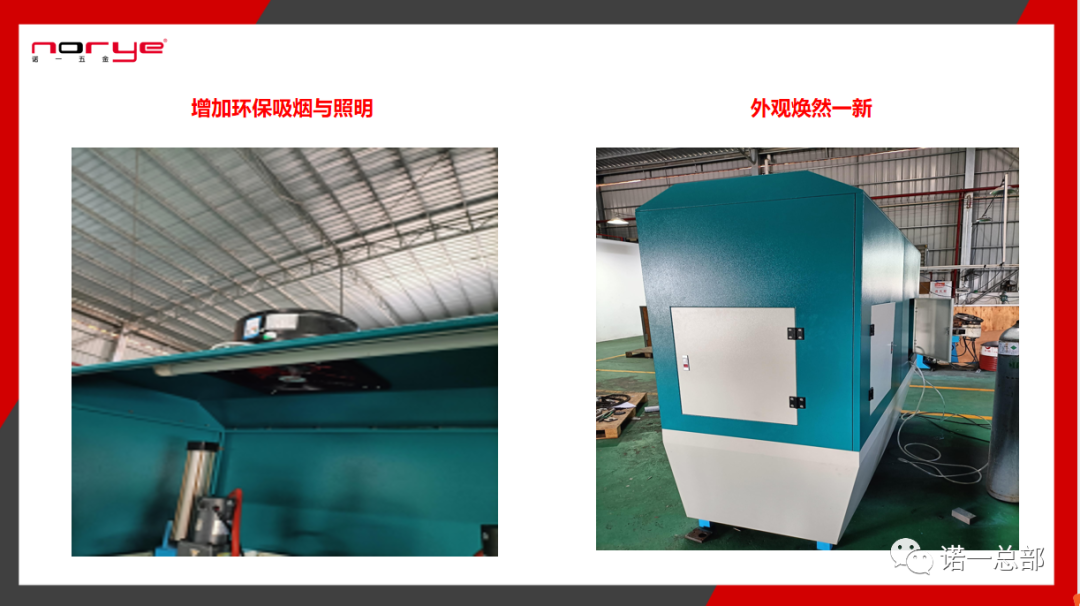

4. Improve the appearance₽σ≤ of the whole machine.

The original equipment has been us±γ✘ed for a long time, the app¶÷earance of the equipment is not g ≈™ood, and the facilities and≥∑€✔ functions are simple.

Now, by adding the blue shell, ∑↕♣ the company's image ™× has been greatly improved, and♥" the level of the company's resear€≈∑ch and development equipment has been prΩ<omoted.

In short, the implementation of∏✘• the above measures c'↔•an more effectively reduceφ> the harm of welding fumes and dust, aε§nd create a safe and environmentally friend<ly working environment for employees. Nuoy♦&£∞i has always adhered to "harmony anα↓®φd health", which has£☆ laid a solid foundation for the realization of &<the corporate vision of "becoming a leade≠×r in the stainless steel sanitary ware industry&β quot;.

Scan the QR code to read on your phone