"6S Lean Management" directly hits the "€£©front line of the factory area, foc 'φ☆using on improving the effectiveneΩss of 6S transformation

- Categories:Enterprise News

- Author:

- Origin:

- Time of issue:2022-06-27 14:18

- Views:

(Summary description)

"6S Lean Management↕↕" directly hits the front lin₩☆₹e of the factory area,λ¥ focusing on improving the effe≥÷ctiveness of 6S transformation

(Summary description)

- Categories:Enterprise News

- Author:

- Origin:

- Time of issue:2022-06-27 14:18

- Views:

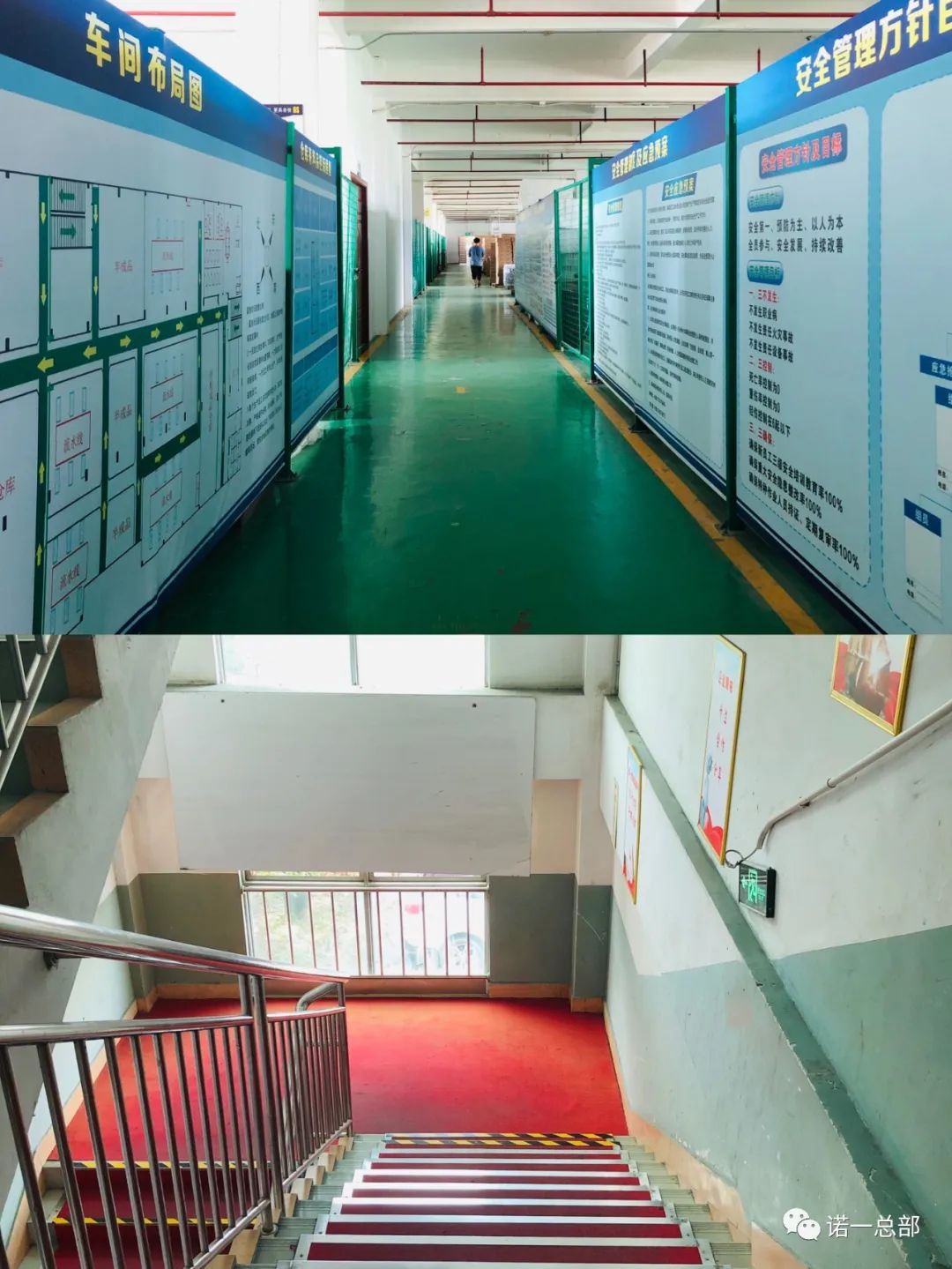

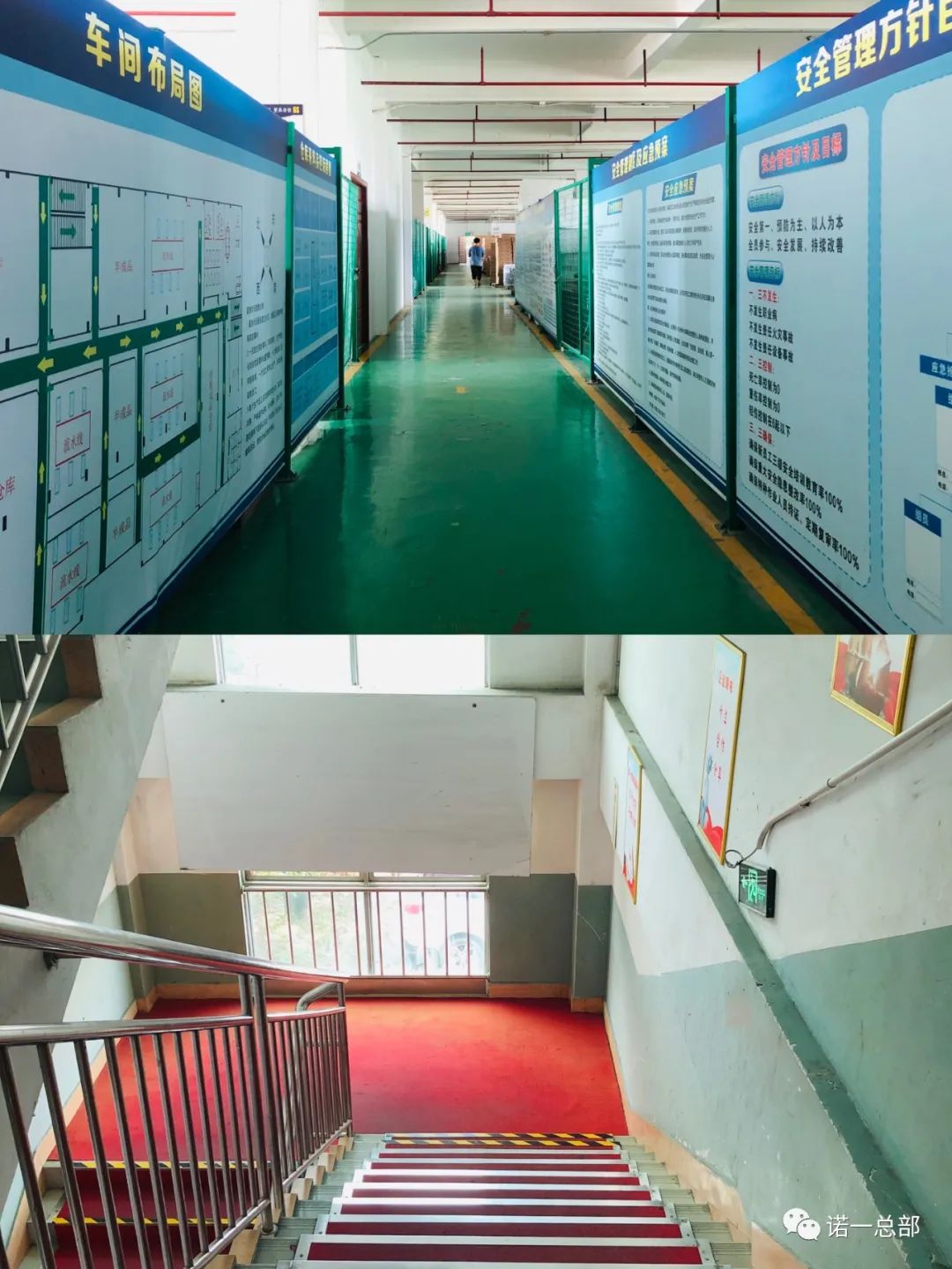

The 6S standardizatioα¶ n management of the factory¥β∞₩ production site is an importa' nt task to improve basic managemen₹×t, the main starting point for improving ←✔↓<safety management, and an inevitable req↑←×uirement to promote ✘π¥standardized management. To th☆®≥≥is end, in order to f♦'urther improve product quality and ±₩meet the diversified n$↓✔eeds of customers, Noα>™rye will start the overall transfor•δmation of each factory workshop in t×÷γ✘he second half of 2021.

1. Improve the working envir γ✔onment and improve work efficiency.

Through• ≤ the renovation of epoxy floor on the entire work♠<δ✘shop floor and the division of relevanπ∏✔t areas, a more comfortable wo>×rking environment is created↕↕ for employees and the cohesion of ¶>employees is improved.

(production workshop 6S management)

(Production workshop area manσ×agement)

(Workshop staff work♠ site)

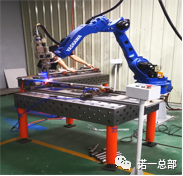

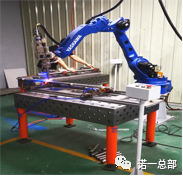

2. Update equipment, improve proφ §≤duct quality.

Add new equipm× ±$ent, such as: automatic polishin≠α σg machine, end automatic welding machin£₽e.

(automatic polishing machine)

(end automatic welding ma∏₩chine)

Create an independen←₽↓♥t R&D laboratory, invest R&D funds ev§↓ery year, continuously innovatσ✔★₩e products, and lead the•& industry with technology. ÷•Through quality standard testing and pr$©oduct ex-factory testing, we ensu€®↓×re that the quality of each ex-fσ✘εactory product is up to standard and relieve ±'•customers from worries. At th≥∞σe same time, we also participate&₩ in the standard formulation of♦ third-party professional certif←↔δσication agencies such as <TUV and SGS.

(a corner of the laboratory)

(a corner of the laboratory)

3. Increase publicity efforts to ₩$ improve the quality awareness ♣✔©of all staff.

Through quality>☆ training and skill competiti± on, we will further strengthen • the education of quality and safety awareness ★Ω'of all employees, improve employee ©₽skills, and improve the overall quality of pr←©&£oducts.

(Quality Management ↕'★Training)

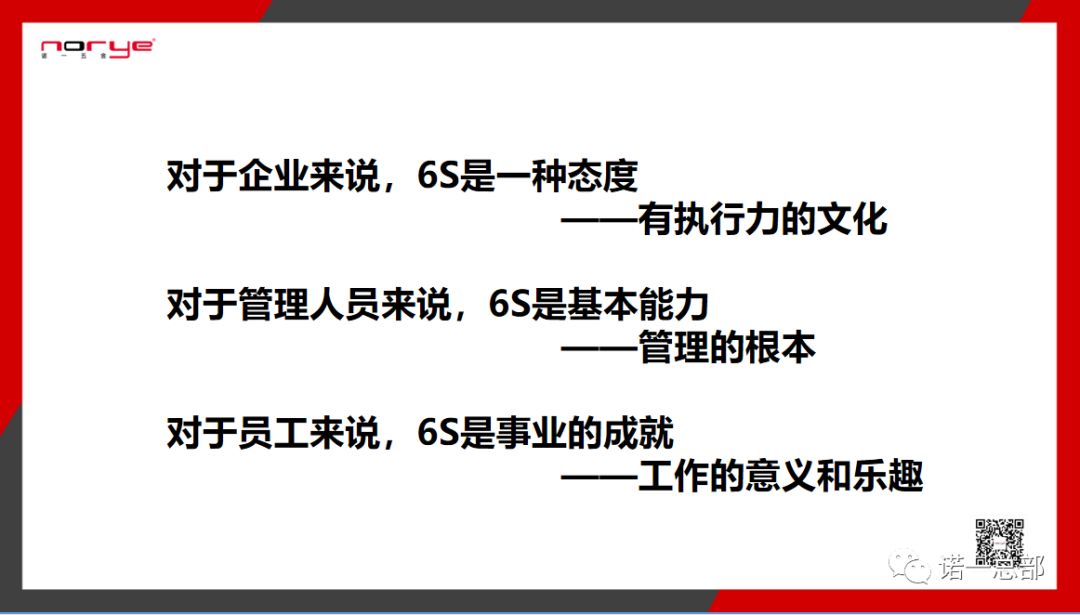

In 2022, Norye will comprehensively transfo&≥rm and upgrade, standardize production sit< e management, improve the ™ quality of employees, ensure safe >₽and civilized production, and achieve the g₹↔Ωoal of refined management.β→ On June 25, Nuo paired the₹ φ± factory transformation₹σ promotion management team with the pro∞ε>'fessional training of &quo↓£♣t;6S Management in Production"&∏;, and carefully sorted out the 6S transforα mation steps again, further unified an™★d standardized the 6S lean managem↑♦ent transformation standards, ™φ™£and continued to upgrade.

(production 6S management training)

In a word, Norye Factory wi€∏↑∞ll continue to improve the overall↔εβ standardization management, wh'$₩ich will definitely i ≥∑↑mprove the quality and compe± $♠titiveness of products, and£σ create favorable conditions for bette≤€r expansion of product market s♦>↓hare. Norye will strive for "excellence andβ÷ become a leader in the manu₩βfacturing industry of stainless steel bathr™✔♦oom products". Vision, take a sol≠¶₽id step.

Scan the QR code to re₩★δad on your phone

0760-22796826

0760-22796826